Creating truly flexible electronics requires applying super-thin layers of conducting materials to already bendable materials—but doing so accurately is difficult. Now, a new form of inkjet printing can allow scientists to deposit thin layers of liquid metal into neat, stretchable circuits.

The researchers, from Purdue University, had the bright idea that liquid metal could be applied via an inkjet print head—but sadly liquid metal doesn’t quite naturally lend itself to being spurted out of a nozzle in that way. So the team created a new liquid metal ink especially, reports PhysOrg.

Taking the liquid metal alloy—in this case gallium-indium—the team dispersed its constituents into nanoparticles using ultrasound, suspending them in ethanol. The resulting liquid can be printed using inkjet nozzles, and then the ethanol evaporates. The new technique will be described in paper to be published in the journal Advanced Materials April 18th.

Once deposited on a surface, the nanoparticles have to be brought back into contact with each other, because the process causes them to gather a layer of oxidized gallium on their surfaces. The application of light pressure causes them to squash together, breaking down that skin and allowing the bulk printed structure to conduct electricity. And, crucially, bend.

In fact, the need to apply pressure might in itself be a bonus: by selectively applying pressure, it could be possible to create customized flexible circuitry from mass-manufactured sheets of printed materials. The next step for the researchers is to explore how different types of base material can be used to create different types of circuitry, and to consider how they’d go about making the materials at scale.. [PhysOrg]

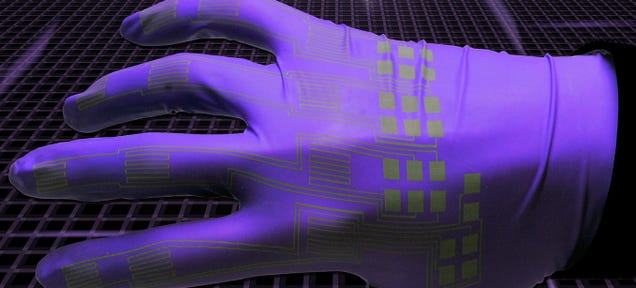

Image by Alex Bottiglio/Purdue University